Mechanical weeders change to blue, and 10m compact disc cultivator debuts in France

14th November 2023

Lemken announced investment in a new manufacturing centre and demonstrated its latest products at a French press event in early September. David Williams was there.

The event opened with an address by Lemken company owner and board member, Nicola Lemken who is the seventh generation of the Lemken family to own and run the 243-year-old business.

Lemken CEO, Anthony van der Ley talked about recent sales performance and confirmed that the results for 2023 appear extremely positive, although his expectations for 2024 are for reduced sales due to European-wide higher interest rates.

Continued investment into products offering even better mechanical weed control includes plant-type recognition by camera using AI. Lemken has a solution for sugar beet growers, capable of recognising the crop from the two-leaf stage.

Investment in weeders

Lemken acquired mechanical weeding machinery specialist, Steketee in autumn 2018. Since the acquisition, Steketee production and sales volumes have tripled, to the extent that the current factory in the Netherlands has been outgrown. In spring 2024, machine production will transfer to a brand-new factory. The 5ha site will accommodate a 10,000m2 production area as well as an Agrofarm where products can be tested and demonstrated. The current manufacturer team of 60 staff will be doubled.

Until now, Steketee products have continued carrying their traditional branding including bright red paint, but from early next year the Lemken name and blue colour will be used instead. “The Steketee name is associated with expertise in this product area, but the Lemken name and colour is better known worldwide, so it makes sense to use these going forward, suggested Anthony. “Our target is to develop 20–25 new markets for the range throughout Europe and overseas.”

The new Thulit weed harrow is described as ‘third-generation’ by Lemken, for its ability to accurately maintain working pressure and depth even across undulating surfaces such as potato ridges. A 12m version will be available in 2025.

Continued investment

Recent developments in the Steketee product line-up includes new camera guidance technology combined with AI for increased suitability in a wider range of crops.

The IC Weeder which removes weeds using pivoting blades is expected to have strong appeal for sugar beet growers as improvements for 2024 will include plant recognition from just two true leaves, whereas current systems recognise the crop only from the four-leaf stage when hoe weed removal treatments are often too late. Lemken says the improved crop recognition capability allows 20% faster operating speed, and crop recognition accuracy of 95%.

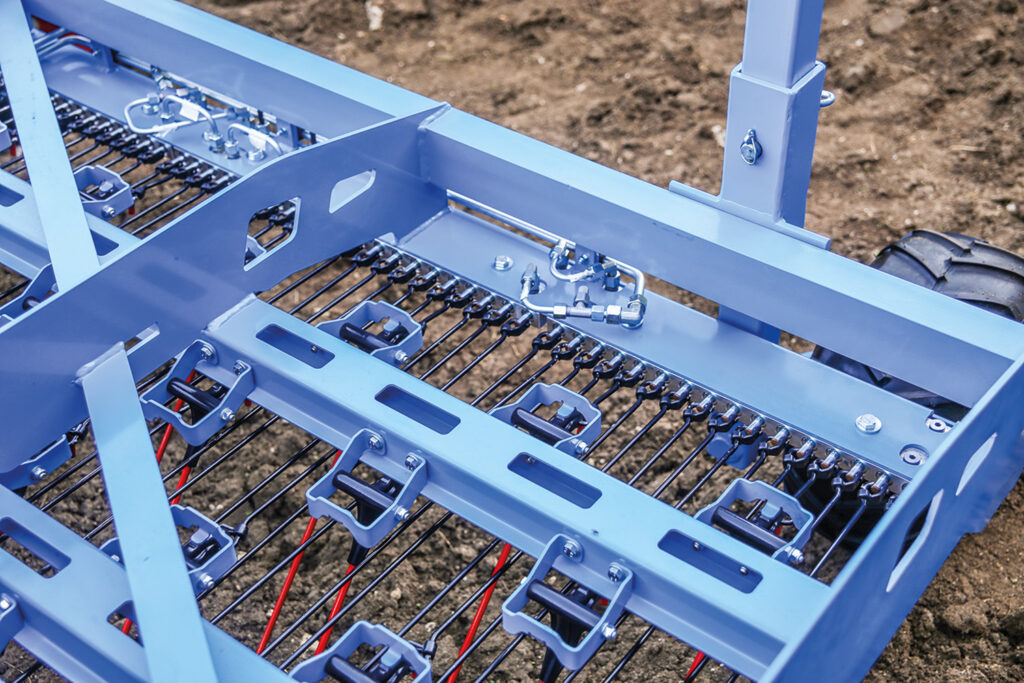

Each Thulit tine is independently mounted on a durable plastic pivot, and working pressure is maintained using miniature hydraulic rams (one for every tine) within the implement frame.

Third-generation harrow

The Thulit spring harrow weeder is completely new. It consists of a bank of close-spaced sprung rake tines and its unique design ensures consistent operating pressure across all the tines regardless of whether some are working on top of ridges while others are in a furrow. This results in effective weed removal across the full working width, even on uneven ground. An adjustable tine angle allows operators to achieve the amount of aggression required. The tines are individually mounted on hinged brackets and connected by tension rods to separate miniature hydraulic rams. An accumulator helps maintain equal hydraulic pressure across the bank of cylinders, regardless of the number of tines in the raised or lowered positions. Lemken argues that the hydraulic pressure control system is simpler and more effective than complex spring arrangements.

The harrow operates by pulling small weeds out of the ground leaving roots exposed on the surface to dry out while other weeds are covered in soil preventing light interception. The spring rake tines aerate soils and break the top crust allowing moisture to penetrate while also levelling the surface.

The harrow is suitable for row crops, vegetables and ridged crops such as potatoes, and it is described by Lemken as a third generation weed hoe, because of its advanced design and ability to achieve the same operating pressure across all the tines no matter how uneven the ground.

The overall tine spacing is 31.25mm equivalent to 32 tines per metre. Lemken explained that mounting the tines across four rows allows large clearance between the tines within each row for trash and plants to flow through easily while achieving up to 97% effective weed control at a working speed of 8kph. Generous underbody clearance beneath the frame means blocking the harrow is almost impossible.

Thulit product specialist, Rik Aelfers is pictured with the new harrow, explaining that the very best weed control is achieved by tackling weeds as early as possible.

Simple set up

Two wheels front and rear control the working depth and the tine operating pressure is set hydraulically. Working pressure for each tine can be adjusted between 100–5,000g. When the working pressure is released, then the tines retract up into the frame achieving a narrower folded width for transport.

Only 50 of the Thulit 6 and 9m rakes will be available for next spring, and a 12m version will be launched in 2025 and is expected to eventually account for most sales.

The new Rubin 10, 10m compact disc harrow was demonstrated for the first time at the event.

New Rubin 10

During the press event, Lemken also demonstrated its brand-new Rubin 10 10m heavy disc cultivator for the first time in Europe, just a few days after its first public viewing at a show in the USA.

The new compact discs are the widest single units from Lemken so far, as achieving this width previously was only possible using two smaller sets mounted side-by-side on the Gigant tool carrier.

The 10m discs achieve high work rates while maintaining excellent ground contour following.

Effective results

The Rubin 10 has 645mm discs and, like smaller versions of the Rubin 10, these are arranged symmetrically to ensure a straight pull for fuel-efficient operation. The serrated concave discs are in two rows and ensure effective mixing and incorporation at shallow working depths down to only 7cm. The discs have an overall 14cm line spacing providing plenty of clearance for trash to follow through and each disc has individual overload compensation, with dampers reducing kick-back and preventing potential damage to the frame.

Hydraulic adjustment allows the working depth to be altered on the move from the cab.

The levelling tines are conveniently adjusted by hand from outside the implement frame ensuring maximum safety. The rear packer features new heavy-duty bearings designed to withstand the heavy working loads including carrying the discs when turning on headlands, and the discs are Lemken Duramaxx faced and 6mm thick for a long working life.

The discs fold to less than 3m wide, under 4m high and can be towed at speeds of up to 40kph.

Contour following

iQ-Contour pendulum-type suspension utilises an articulated chassis which allows the front and rear sections to move vertically. Up to 4.5 degrees of vertical downward movement and up to 6.0 degrees upward movement maintains excellent ground contour following, even across severe ground undulations.

Towing is by a drawbar eye or ball coupling and a hydraulic support ensures easy attachment to the tractor, while the hydraulic operated rear packer makes it easy to reverse the heavy discs into field corners and work around obstructions.

Nichola Lemken is pictured with Lemken CEO Anthony van der Ley at the first demonstration of the new 10m Rubin 10.

Deliveries for next autumn

Lemken said at the event that the Rubin 10 10m discs are the widest 645mm discs currently available and that they are designed for use with tractors from 350–500hp. The main design advantages include accurate depth control and ground contour following as well as exceptional convenience for transport, as the set folds to under 3m width and 4m high and is approved for towing at speeds up to 40kph.

Deliveries commence in time for next autumn cultivations and the price is approximately €170,000.